|

Sub-Micron LIGA Process |

◆ In order to fabricate sub-micron

structures with high aspect ratio, we are studying about sub-micron

LIGA (Lithographie, Galvanoformung, Abformung) process.

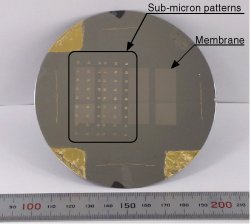

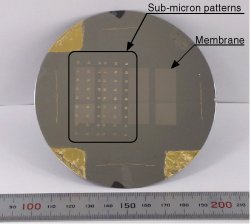

◆ One of the most important things

for sub-micron LIGA process is fabrication of an high contrast X-ray

mask with sub-micron resolution. It is realized by combination of

electron direct lithography using thick resist and Au

electroforming (Fig.1).

◆ In order to fabricate sub-micron

structures, a warp in a sample and heat generation under SR X-ray

irradiation was investigated. It is important for X-ray

lithography with sub-micron resolution to control a gap between a

resist and an X-ray mask precisely, because Fresnel diffraction

has influence on lithography accuracy by the gap. In order to

control the gap precisely, PMMA resist was polymerized without

residual stress and a warp in a sample by controlling of

polymerization process (Fig.2).

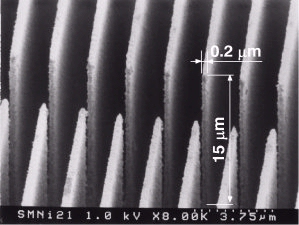

Figure 3

shows profiles of the measured surface temperature of an Au

absorber, a SiC membrane and a PMMA resist under SR X-ray

irradiation. The surface temperature indicated an increase under

SR X-ray irradiation. In order to avoid these influences, density

of SR X-ray irradiation energy is reduced by means of scanning

exposure. As a result, sub-micron Ni structures with an aspect

ratio of 75, corresponding to 0.2 um width and 15 um height, were

fabricated (Fig.4).

|

Fig.1 An fabricated X-ray mask.

|

Fig.2 Residual stress of PMMA resist.

|

Fig.3 Profiles of the

measured surface

temperature.

|

Fig.4 sub-micron Ni

structures with

an aspect ratio of 75.