Fabrication

of High Aspect Ratio Electrostatic Micro Actuators |

◆ LIGA process is attracting attention as a fabrication technique to make three dimensional microstructures. The process is composed of deep x-ray lithography using synchrotron radiation, electroforming and molding. There are many reports about microactuators fabricated by surfacemicromachining. The height of the microactuators is limited to about 1 to 10 micrometer in surfacemicromachining. However, the LIGA process can fabricate high aspect ratio microactuators with height of more than 100 micrometer. In this work, fabrication of electrostatic microactuators as an application of the LIGA process has been investigated by using a compact synchrotron radiation source "AURORA".

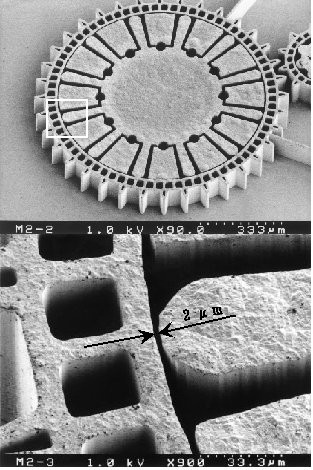

◆ Figure 1 shows a basic structure of microactuators in this work. The structure is composed of 100 micrometer high Ni microstructures, a seed layer for electroforming, an isolation layer of 3 micrometer thick SiO2, and a Si wafer. The Ni microstructures act a movable electrode, fixed electrodes, a spring beam and an anchor portion. The movable electrode is separated from the substrate by sacrificial layer etching of the SiO2. Figure 2 shows a wobble motor with 1 millimeter diameter, 100 micrometer height, 2 micrometer minimum width and gap, and then maximum aspect ratio of 50 after Ni electroforming.

◆ The roughness of sidewalls is an important factor for the performance of high aspect ratio microstructures. The sidewall roughness of the Ni microstructure was measured by atomic force microscope (AFM). Figure 3 shows the surface profile of the sidewall roughness of the Ni microstructure. The peak to valley in the measurement area was 651 nanometer, which was equal to the roughness of the absorber sidewall. The vertical average roughness of the sidewall was 23.1 nanometer. It can be considered as the real finish roughness of the deep X-ray lithography.

◆ These microactuators can be applied to high accuracy positioning actuators.

Fig.1 A basic structure of microactuators.

Fig.2 SEM images of a wobble motor after Ni electroforming.

Fig.3 Surface

profile of the sidewall roughness of the

Ni microstructure measured by AFM.