Three-dimensional

Micromachining of PTFE |

◆ Polymers of fluorine like PTFE (polytetrafluoroethylene) etched directly by irradiated SR light. This is a new process called TIEGA (Teflon included etching galvanicforming) that fabricate microparts without any process gases. SR etching in TIEGA is a dry etching process, and the etching rate of heating PTFE at 200 centi-grade is on the order of 60-100 um in a vacuum and 6μm under He of 1 atmosphere. Moreover the etched surfaces are so smooth. So, SR etching might have a potential as a three-dimensional (3-D) micromachining by combining a scanning stage with high degree of freedom. We propose SR beam direct writing (Fig. 1) using SR etching as a new approach to fabricate 3-D microstructure of PTFE.

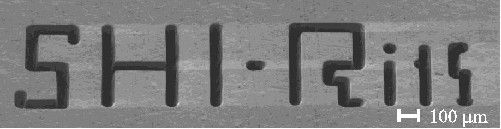

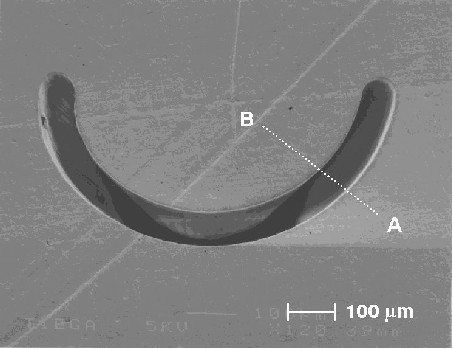

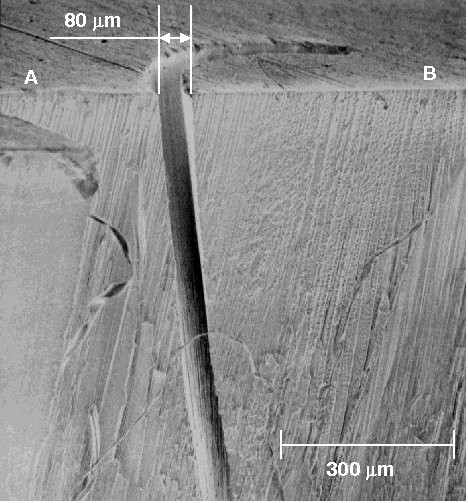

◆ 3-D micromachining was carried out without using any masks in a vacuum. Direct writing using the SR beam through a pinhole with a diameter of 80μm and heating PTFE at 200 centi-grade carried out this experiment. Figure 2 shows fabrication examples created by SR beam direct writing. PTFE was oriented perpendicular to the SR beam and irradiated controlling the X-Y stage. Figure 3 (a), fig. 3 (b) shows a cone shape microstructure created in PTFE. PTFE was installed at a slant of 15 degrees against the SR beam and irradiated controlling the rotating stage. The fabricated corn shape microstructure has a diameter of 600μm in the surface and an achieved depth of 1000μm.

Fig. 1 Schematic

diagram of experimental

for SR beam direct writing.

Fig. 2 Fabrication examples by SR beam direct writing.

(a)surface

Fig. 3 Corn shape PTFE microstructure

(b)cross section.

Fig. 3 Corn shape PTFE microstructure