STORY #4

Toward the Era of Society 5.0:

Empowering energy users in producing their own energy: sustainable biogas production from household food waste

Gian Powell Marquez, D.Eng.

(Doctor of Engineering)

Associate Professor, College of Global Liberal Arts

Bringing innovative ideas to life:

Biogas generation using 3D printer

Food waste generated by households is a part of everyday life. As the population grows, the amount of food waste has continued to increase globally, reaching 1.3 billion tons in 2011. In urban areas, it comprises around 80% of the total waste generated. Greenhouse gases emitted from food waste incineration and related processes account for up to 10% of global emissions.

Gian Powell Marquez is trying to upcycle food waste into biogas, a biofuel that can be used as a heat source for cooking and heating, using several microorganisms including methanogenic archaea (methanogens) that degrade organic matter into methane gas and carbon dioxide. The search for alternative fuels is an urgent task for humankind, as there are currently concerns about dwindling natural gas supplies.

The idea of upcycling food waste is not new. There are already “composting” systems that use earthworms and other organisms to produce compost for agricultural and gardening use, and devices that use microorganisms to produce gas. However, composting produces fertilizer, and not energy. Because conventional biogas generators are large in size and produce a foul odor during the degradation process, they are difficult to fit into urban households. To resolve this problem, Marquez has developed “Se-CoBiDS,” or Seamless Compact Biogas Digestion System for urban use.

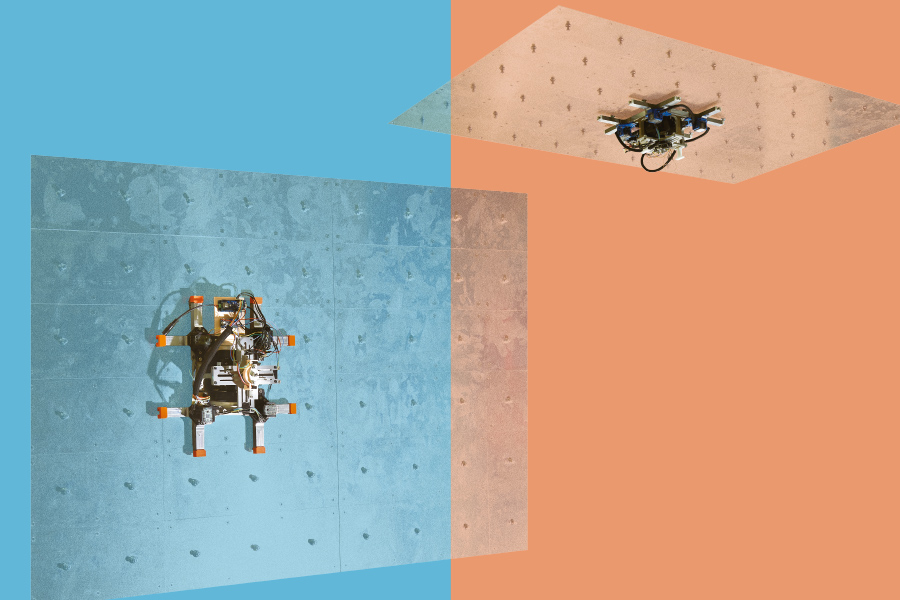

Se-CoBiDS is a box-like device the size of a small refrigerator, which incorporates two tanks for waste hydrolysis and methane production. The hydrolysis tank contains microorganisms that are different from methanogens and degrade organic matter remaining in the waste, including carbohydrates and proteins, into more basic components like glucose and amino acids. The next tank is an oxygen-free tank in which the methanogens, which are anaerobic, degrade these components into gases, primarily methane, through a process called “anaerobic digestion.”

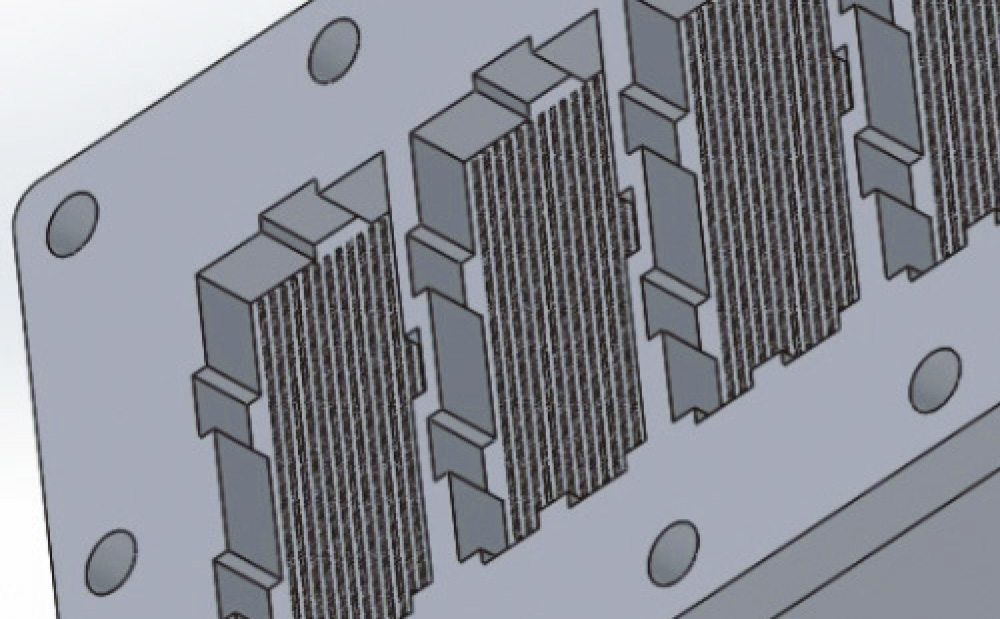

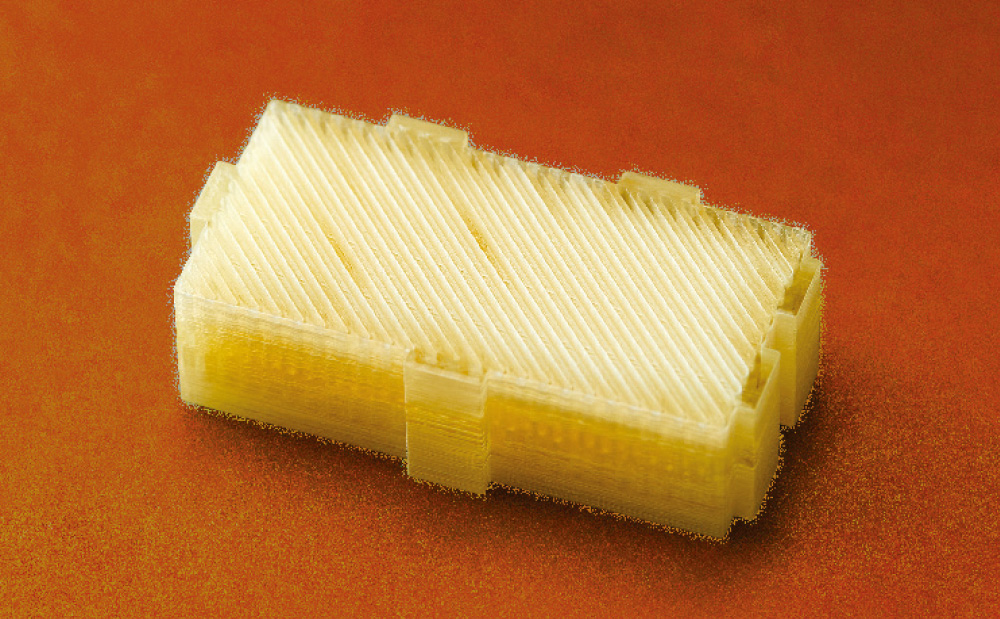

Marquez explains, “I am currently working on the development of this second tank. With a 3D printer, I have created several parts with different structures to compare the efficiency of anaerobic digestion to get the highest yield of methane.” For example, since the methanogens grow on the surfaces of rocks or resins as thin biofilms, the tank needs a bed to offer a scaffold for the biofilm.

“Before the invention of 3D printers, there had been no active research on the differences in biogas production efficiency based on the structure of the generator,” says Marquez. “That is because the researchers in those days could only obtain the instruments and parts they required for their study from outside contractors, and this was expensive and time-consuming. On the contrary, 3D printing is simple and inexpensive, and we can create multiple patterns and compare them very easily. For Se-CoBiDS, I am planning to produce most of the parts, including the tank, with a 3D printer.”

Marquez’s interest in generating biogas through anaerobic digestion was sparked by the seaweed that washed up on the shores of his home country, the Philippines. “During the 2008 Beijing Olympics, it was reported that a massive amount of seaweed had washed up on the Chinese coasts, including some competition venues. Although not in the same quantity as at that time, we had similar seaweed drifts occurring in the Philippines as well. This incident inspired me to explore the possibility of using the abundant seaweed as an alternate bioenergy source. This could help us avoid consuming biomass of terrestrial origin, especially grains, for energy production and not add to the competition with food production.”

As some methanogens are inhibited by salt, it is necessary to use marine microorganisms to decompose seaweed. After studying at the graduate school of Nagoya University, Marquez began his research on biogas production using seaweed and marine microorganisms. “My supervisor at that time had already developed a compact and highly efficient biogas generation system using food waste, and he had a patent for it. But even though it was more ‘compact’ compared to the earlier systems, it was still not small enough to be used in an ordinary household kitchen,” he recalls.

Marquez’s goal is to develop a system that blends naturally into the general household, such that people are not made conscious of the biofuel-producing equipment in operation. The methane gas produced will be stored in an outdoor storage tank. For safety reasons, he would prefer to use tanks filled with porous activated carbon or other materials to absorb the gas rather than high-pressure cylinders. “I want the device to be easily maintained. I would like its users to be able to replace its parts easily with a single touch, just like replacing a paper bag of a vacuum cleaner.”

The potential application of Se-CoBiDS is not limited to food waste recycling. By changing the microorganisms settling on its bed, it will become possible to decompose other wastes. In the future, it could also be used to treat wastewater and sewage.

The conventional problem of food waste treatment might just get resolved in an innovative manner, incorporating modern technology – the 3D printer – with the old. Marquez, who is working on a biogas digester at Biwako-Kusatsu Campus, emphasizes that even methods and technologies that look obsolete can become the seed of innovation when combined with innovative ideas. He concludes with a message, “Ritsumeikan University has a system to nurture the seeds and an environment in which we can easily find collaborators. I would like to encourage students to develop their innovative thinking skills and give shape to their ideas.”

- Gian Powell Marquez, D.Eng. (Doctor of Engineering)

- Associate Professor, College of Global Liberal Arts

- Specialties: Bio-related chemistry, Environmental chemistry, Energy chemistry, Molecular biology, Applied microbiology

- Research Themes: Bioenergy, Sustainability, Marine Biomass, Green Economy